Chinese electric vehicle maker BYD is planning to build a $250 million factory in Vietnam to produce electric vehicle parts to expand its market share globally.

According to Reuters, Chinese automaker BYD is planning to build a spare parts factory in Vietnam. This is a move to reduce dependence on component manufacturers in China, strengthen supply chains in Southeast Asia and move towards expanding market share globally.

Accordingly, BYD will invest 250 million USD (equivalent to about 6,000 billion VND) to open a factory in Vietnam. Currently, negotiations are underway to make a decision on the location of the plant, which is expected to start construction in mid-2023.

Founded in 1995, BYD focuses on developing electric vehicles such as cars, buses, bicycles, electric trucks, and also developing solar panels and rechargeable batteries (for mobile phones and vehicles).

Before being known as an electric vehicle manufacturer, BYD has grown rapidly to become the largest rechargeable battery manufacturer in China as well as the 4th largest in the world and was honored by Bloomberg for its progress in 2010. Then, with the support of the Chinese government, the company started to move into the production of electric vehicles and achieved remarkable success.

Also in 2010, the company was ranked in the top 10 of the world’s most innovative enterprises by BusinessWeek, thanks to its groundbreaking innovations in the development of rechargeable batteries. BYD shows full initiative in controlling the supply chain, especially with their electric vehicle batteries.

Currently, BYD Auto and BYD Electric are the two largest and most well-known subsidiaries of this group. In particular, the company’s automotive segment has been relatively developed many years ago, when they delivered nearly 450,000 vehicles to customers in 2009 with the F3 topping the chart in terms of sales.

In September, BYD announced the construction of an electric vehicle assembly plant in Thailand with an annual capacity of 150,000 vehicles, starting operation from 2024.

Backed by billionaire Warren Buffett, BYD has become one of the largest electric car companies in the world. Summing up in 2022, the company achieved sales of nearly 1.9 million vehicles and aims to sell 4 million vehicles this year. Like Tesla, the Chinese electric vehicle maker controls much of its supply chain including battery technology, which helps BYD not be too affected by the disruption of the global component supply chain.

It is known that BYD currently has an Ipad assembly factory in Phu Tho. Setting up a component factory in Vietnam, right next to Thailand, will help the Chinese automaker to optimize transportation and production costs. It is not clear what parts BYD’s components plant will make and whether it will include batteries or battery pack.

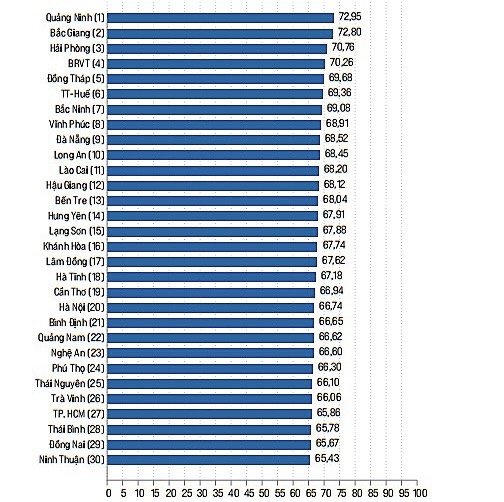

Over the last few years, many large technology corporations in the world have invested or plan to invest in large factories in Vietnam, most recently, Compal Group has invested in a $260 million project in Thai Binh, Quanta Group plans to invest in a factory to produce Macbooks for Apple, BOE Group plans to invest in a 250 million USD factory with a scale of 100 hecta, . . .

The fact that a series of large corporations are expected to invest in Vietnam with very large-scale projects shows that Vietnam is an attractive destination for foreign corporations.